Tel: +86-0731-88672086 E-mail: info@great-pipe.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Alloy Steel Pipe Fitting, Alloy Steel Welded Fitting, Alloy Steel Tee, Alloy Steel Reducer, Alloy Steel Elbow

Bending Radius: R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

A/SA234 WP1, WP5, WP9, WP11, WP22, WP91 | A/SA182 F1, F5, F9, F11, F22, F91, A420 WPL3, A420 WPL6, A350 LF2, LF3, A105,A515 GR.60, A515 GR.70, A516 GR.60, A516 GR.70, MSS SP75 WPHY42/46/52/56/60/65/70/80, A860 WPHY42/46/52/56/60/65/70/80, A694 F42/46/52/56/60/65/70/80

| SKU: | |

|---|---|

| Availability: | |

|

| |

▇ ▍ Description

We manufactured to ASTM A234 includes the grades of WP1, WP12 CL1, WP12 CL2, WP11 CL1, WP11 CL2, WP11 CL3, WP22 CL1, WP22 CL3, WP24, WP5 CL1, WP5 CL3, WP9 CL1, WP9 CL3, WP91, WP911, WP92. It can be widely used in moderate or high-temperature service. Our alloy steel flange products include threaded flange, weld neck flange, slip on flange, socket weld flange, blind flange, lap joint flange, plate flange. The most common product form of ASTM A234 is butt welding pipe fittings manufactured to ASME B16.9. The Butt weld alloy steel pipe fittings can be made from either seamless pipes, or fusion-welded pipes which shall be with filler metal added and shall conform to the chemical requirements of the standard specification.

(1)Alloy Steel Pipe Fittings Production Range

| Grade Specification | A/SA234 WP1, WP5, WP9, WP11, WP22, WP91 | A/SA182 F1, F5, F9, F11, F22, F91, A420 WPL3,A420 WPL6,A350 LF2, LF3,A105,A515 GR.60,A515 GR.70,A516 GR.60,A516 GR.70,MSS SP75 WPHY42/46/52/56/60/65/70/80,A860 WPHY42/46/52/56/60/65/70/80,A694 F42/46/52/56/60/65/70/80 |

| Type | Seamless / Welded / Fabricated / Forged |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Range | ½”NB to 48″NB in Sch 10s, 40s, 80s, 160s, XXS. |

| Dimensions | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

(2)Buttweld Alloy Steel Pipe Fittings

Seamless/ Welded 100% Radiography Tested

| Products | Size | |

| Alloy Steel Elbows – Long Radius | Alloy Steel Stub Ends | Sizes 1/2″ – 48″ |

| Alloy Steel Elbows – Short Radius | Alloy Steel Crosses | |

| Alloy Steel Reducing Elbows | Alloy Steel Reducing Crosses | |

| Alloy Steel 45° Elbows | Alloy Steel 180° LR Return Bends | |

| Alloy Steel Tees | Alloy Steel 180° SR Return Bends | |

| Alloy Steel Tees | Alloy Steel Pipe Bends / Piggable Bends | |

| Alloy Steel Reducers | Alloy Steel Couplings | |

| Alloy Steel Concentric Reducers | Alloy Steel Pipe Nipples | |

| Alloy Steel Eccentric Reducers | Alloy Steel Forged/Plate Cut Rings | |

| Alloy Steel 3D Elbow | Alloy Steel End Caps | |

| Alloy Steel 5D Elbow | Alloy Steel Forged / Plate Circles | |

(3)High Pressure Forged Alloy Steel Pipe Fittings

Threaded and Socket Weld Pipe Fittings

| Products | Size | |

| Alloy Steel 90° Elbows | Alloy Steel Couplings | Sizes 1/8″ – 4″Pressure Ratings – 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Alloy Steel 45° Elbows | Alloy Steel Reducers | |

| Alloy Steel Street Elbows | Alloy Steel Inserts | |

| Alloy Steel Tees | Alloy Steel Caps | |

| Alloy Steel Crosses | Alloy Steel Unions | |

(4)Alloy Steel Flanges

Forged and Plate Flanges

| Grade/Specification | ASTM / ASME A182 F1 / F5 / F9 / F11 / F22 / F91 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½” to 36″ |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Product | Size | |

| Alloy Steel Slip-On Flanges | Alloy Steel Threaded Flanges | 1/2″ – 36″ Raised Face or Flat Face |

| Alloy Steel Weld Neck Flanges | Alloy Steel Socket Weld Flanges | |

| Alloy Steel Blind Flanges | Alloy Steel Reducing Flanges | |

| Alloy Steel Lap Joint Flanges | Alloy Steel Plate Flanges | |

▇ ▍ Dimension of Alloy Steel Pipe Fittings

| NPS | AS 90 Deg Elbows | AS 45 Deg Elbows | AS 180 Deg Return Long Radius | |||||||||||

| Long Radius | Short Radius | 3R | Long Radius | 3R | STD | XS | ||||||||

| STD | XS | SCH. 160 | XXS | STD | XS | STD | XS | STD | XS | STD | XS | |||

| ½ | 0.18 | 0.25 | * | * | * | * | * | * | 0.09 | 0.19 | * | * | 0.35 | * |

| ¾ | 0.19 | 0.25 | * | * | * | * | * | * | 0.09 | 0.19 | * | * | 0.4 | 0.65 |

| 1 | 0.4 | 0.5 | 0.6 | 0.75 | 0.25 | * | * | * | 0.25 | 0.31 | * | * | 0.75 | 1 |

| 1¼ | 0.6 | 0.9 | 1 | 1.38 | 0.4 | * | * | * | 0.38 | 0.5 | * | * | 1.25 | 1.75 |

| 1½ | 0.9 | 1.15 | 1.8 | 1.5 | 0.56 | 0.75 | * | * | 0.4 | 0.69 | * | * | 1.88 | 2.39 |

| 2 | 1.6 | 2.2 | 3.25 | 3.5 | 1 | 1.5 | 3 | 4 | 0.81 | 1.19 | 1.5 | 2.1 | 3.23 | 4.4 |

| 2½ | 3.25 | 4 | 5.13 | 7 | 2.13 | 2.8 | 6 | 8 | 1.75 | 2.13 | 3 | 4 | 6.5 | 8 |

| 3 | 5 | 6.5 | 8.5 | 11 | 3 | 4.25 | 10 | 13 | 2.63 | 3.5 | 5 | 7 | 10.25 | 13 |

| 3½ | 6.75 | 8.35 | * | 16 | 4.5 | 6 | 13 | 18 | 3.5 | 4.5 | 7 | 9 | 13 | 16.75 |

| 4 | 9 | 13.5 | 18 | 20 | 6.25 | 8.5 | 18 | 25 | 4.5 | 6.1 | 9 | 13 | 18.5 | 25 |

| 5 | 15 | 22 | 32 | 36 | 9.6 | 14 | 29 | 43 | 7.5 | 10.7 | 15 | 22 | 30 | 44 |

| 6 | 24.5 | 35 | 57 | 65 | 18 | 23 | 45 | 70 | 12 | 17.5 | 23 | 35 | 50 | 70 |

| 8 | 50 | 71 | 120 | 118 | 34 | 47.5 | 90 | 140 | 23 | 35 | 45 | 70 | 95 | 142 |

| 10 | 88 | 107 | 260 | * | 58 | 70 | 159 | 218 | 43 | 53 | 80 | 109 | 117 | 215 |

| 12 | 125 | 160 | 450 | * | 80 | 104 | 233 | 310 | 62 | 84 | 117 | 155 | 230 | 320 |

| 14 | 160 | 205 | 572 | * | 105 | 140 | 298 | 400 | 80 | 100 | 149 | 200 | 325 | 400 |

| 16 | 206 | 276 | * | * | 132 | 174 | 390 | 520 | 100 | 135 | 195 | 260 | 412 | 550 |

| 18 | 260 | 340 | * | * | 167 | 219 | 495 | 660 | 126 | 167 | 248 | 330 | 510 | 690 |

| 20 | 320 | 420 | * | * | 210 | 275 | 610 | 810 | 160 | 206 | 305 | 405 | 640 | 830 |

| 22 | 394 | 520 | * | * | * | * | 735 | 980 | 197 | 260 | 368 | 490 | 787 | 1040 |

| 24 | 460 | 600 | * | * | 298 | 392 | 875 | 1170 | 238 | 300 | 438 | 585 | 890 | 1200 |

| 26 | 550 | 729 | * | – | – | – | 1030 | 1370 | 275 | 365 | 515 | 685 | – | – |

| 30 | 734 | 975 | – | – | – | – | 1370 | 1830 | 367 | 488 | 685 | 915 | – | – |

| 36 | 1062 | 1412 | – | – | – | – | 1970 | 2630 | 531 | 706 | 985 | 1315 | – | – |

▇ ▍Application

Alloy Steel Buttweld Fittings is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. It has many inherent advantages such as it provides permanent leak proof to the fittings. The continuous metal structure formed between fitting and pipe gives strength to the system. Smooth inner surface and gradual directional changes minimize the action of corrosion and erosion and reduce pressure losses and turbulence. It doesn't make it any less vulnerable to rust when exposed to the elements since it is ferrous.

Alloy Steel Weld Fittings is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. It is mainly used small pipe diameters generally for piping whose nominal diameter is NPS 2 or smaller. Its tensile strength of is between 758-1882 MPa which is higher than the tensile strength of stainless steel.

Low Alloy Steel Fittings is generally defined as having a 1.5% to 5% total alloy content. Its common alloying elements are chromium, manganese, silicon, molybdenum, nickel and vanadium. It is used for manufacturing of heating elements.

Alloy Steel Elbow is a key parts in a piping system for changing the fluid flow direction. It is useful to connect two pipes with different or same nominal diameters, and to make the pipe turn to a certain direction of 45 deg or 90 deg.

Alloy Steel Tee has three branches that can change fluid direction. It is widely used in pipe networks for convey liquids and gases. It is in T-shaped having two outlets, at 90° to the connection to the main line. It is a pipe short piece with a lateral outlet. It is widely used as pipe fittings.

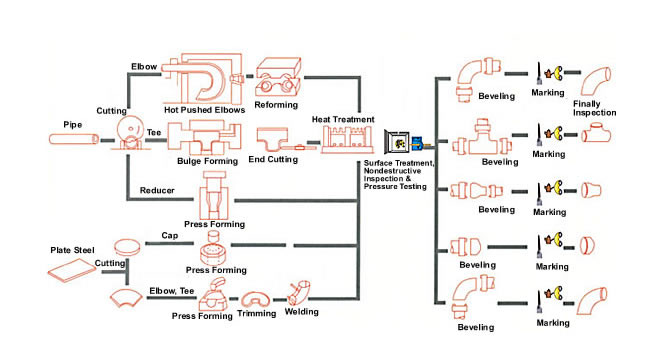

▇ ▍Process of Alloy Steel Pipe Fittings